Why Draw a Master Production Plan

Master Production Schedule (MPS) is a tool for manufacturers to ensure the right products are made at the correct fourth dimension and in the correct quantities.

This post will reply questions on MPS, the steps involved, its functions, and its benefits. You lot tin download different MPS templates at the end of this post.

Definition of Chief Production Schedule

Master Production, as the proper name suggests, decides what products demand manufacturing and the accurate fourth dimension to manufacture that product.

Principal Production Scheduling (MPS) is a process in manufacturing to make up one's mind which products to produce and how much quantity is required to meet the requirement in a given interval of time.

It can exist used in any industry where a good bargain of production is necessary, such as manufacturing, structure, and logistics.

There are many different versions of it, but all achieve the same goal: creating a plan that allocates resources to deliver products or services on time and at the lowest possible cost.

Information technology is a production planning tool that helps companies manage their finite resource to produce the greatest possible output. Equally a result, companies using MPS report improved efficiency, reduced waste, and increased customer satisfaction.

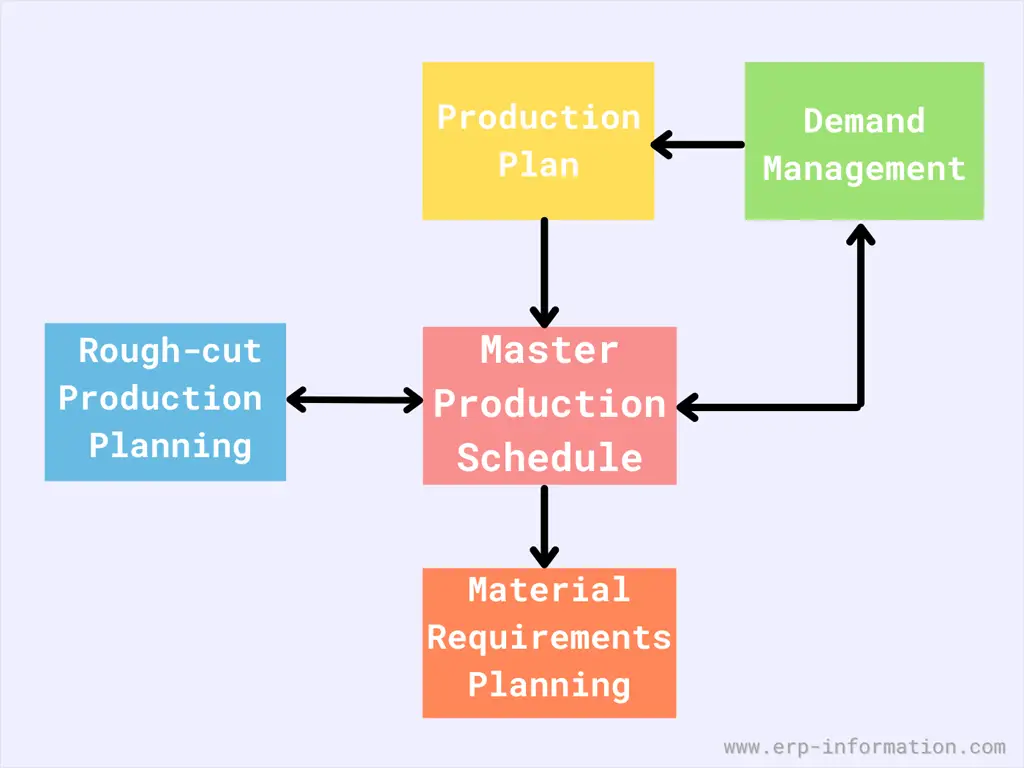

Bill of Materials (BOM) and Material Requirements Planning (MRP) are the two crucial aspects.

The Bill of Materials BOM then identifies the raw materials required to produce finishing appurtenances.

What is the production schedule?

The production schedule is the sequence of steps or operations necessary to produce a product.

The production schedule for a chocolate bar, for example, might involve the following steps:

1. obtaining cocoa beans

2. roasting the beans

3. grinding the beans into a pulverisation

4. adding carbohydrate and other ingredients

5. shaping the chocolate bars and

6. packaging the chocolate bars.

Importance of Chief Production Schedule(MPS)

MPS is an integral office of an Enterprise Resources Planning system. Information technology provides the near constructive planning functionality by extracting the actual need and supply data to deliver precise production plans.

These plans assist manufacturers in quickly achieving their production goals and minimize the cost incurred on the procurement.

While performing calculations of operating expenses, information technology pays special heed to the manufacturing capacity of the product plant.

Automated initiation of the Material Resource Planning management procedure and generation of the purchase social club takes place soon after the analysis and the approval of the production orders.

Aside from all these implications, it acts as a protective barrier against shortages, unexpected scheduling snafus, and inefficient allocation of resources.

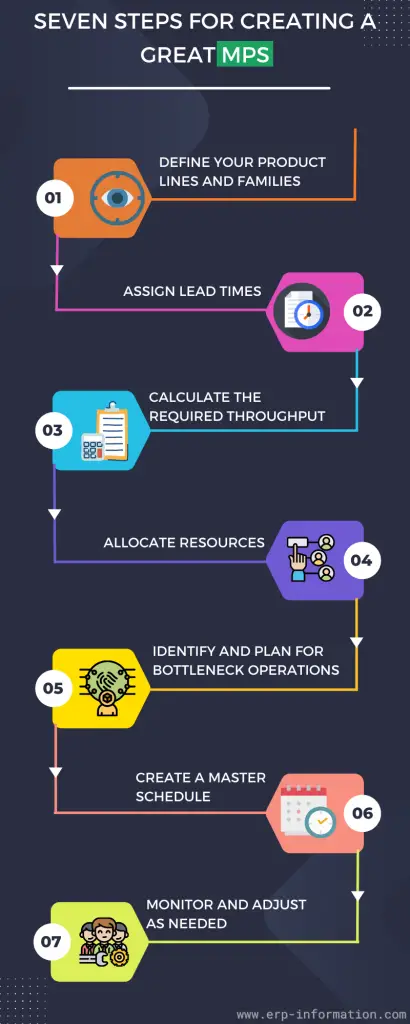

Seven proven steps for creating dandy MPS

Define your product lines and families

Product lines represent unlike categories of products, while product families represent similar products inside a line. You'll need to ascertain both to create an accurate MPS.

Assign lead times

Lead times are the fourth dimension it takes from when you place an lodge until you receive the product. Y'all'll need to know this data to calculate your required throughputs (more on that subsequently).

Calculate the required throughput

The required throughput is the number of products yous demand to produce each day to meet customer demand. This figure can vary depending on your business and production needs, so it'southward important to calculate it accurately.

Allocate resource

Once you lot know the throughputs needed for each product line/family, y'all'll need to allocate the necessary resources (staff, equipment, etc.) to come across those demands.

Place and plan for bottleneck operations.

A bottleneck operation is an area of your production process that'south unable to come across customer demand. You'll need to identify these areas and decide how much boosted capacity you lot need to meet need.

Create a master schedule

This is where the real work of creating an MPS begins. Using steps ane through v information, create a primary schedule that shows when the company will produce each product line/family.

Monitor and suit as needed

As with any plan, your schedule volition require regular monitoring and adjustment to ensure that it's coming together your business needs. And so make sure to revisit the previous step regularly to ensure that your master schedule is up-to-date.

Three tips for creating MPS

Create a realistic schedule

One of the most important things to keep in mind when creating your primary production schedule is to be realistic about the corporeality of product. Don't try to cram too many items into your schedule, or you'll overschedule yourself and encounter bug.

Starting time with your high-priority items.

When creating your master product schedule, starting time by listing the most necessary items for your concern. These items should be at the superlative of your list and given priority handling.

Suspension down each task into smaller steps

When creating a primary production schedule, it'southward of import to pause each job down into smaller steps to estimate meliorate how much time it will take to consummate. This will aid yous ensure that each job is completed on time.

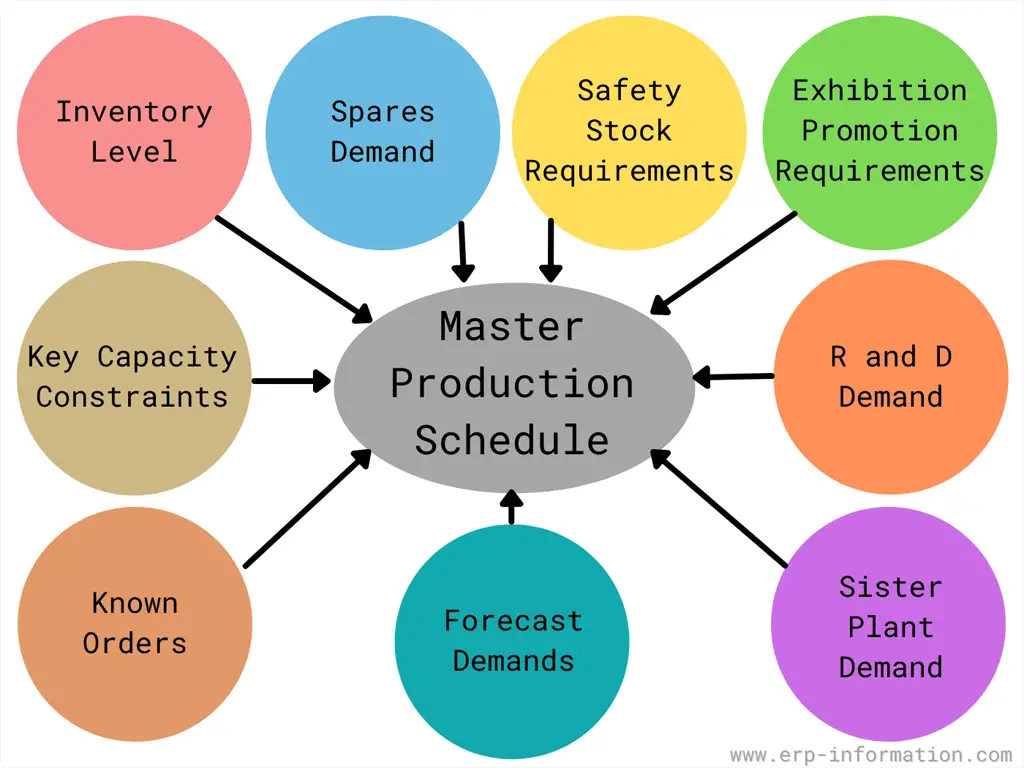

Inputs to MPS

Following is the list of inputs,

- Forecast demands

- Known orders

- Key chapters constraints

- Inventory level

- Spares demand

- Rubber stock requirements

- Exhibition promotion requirements

- R & D demands

- Sis constitute need

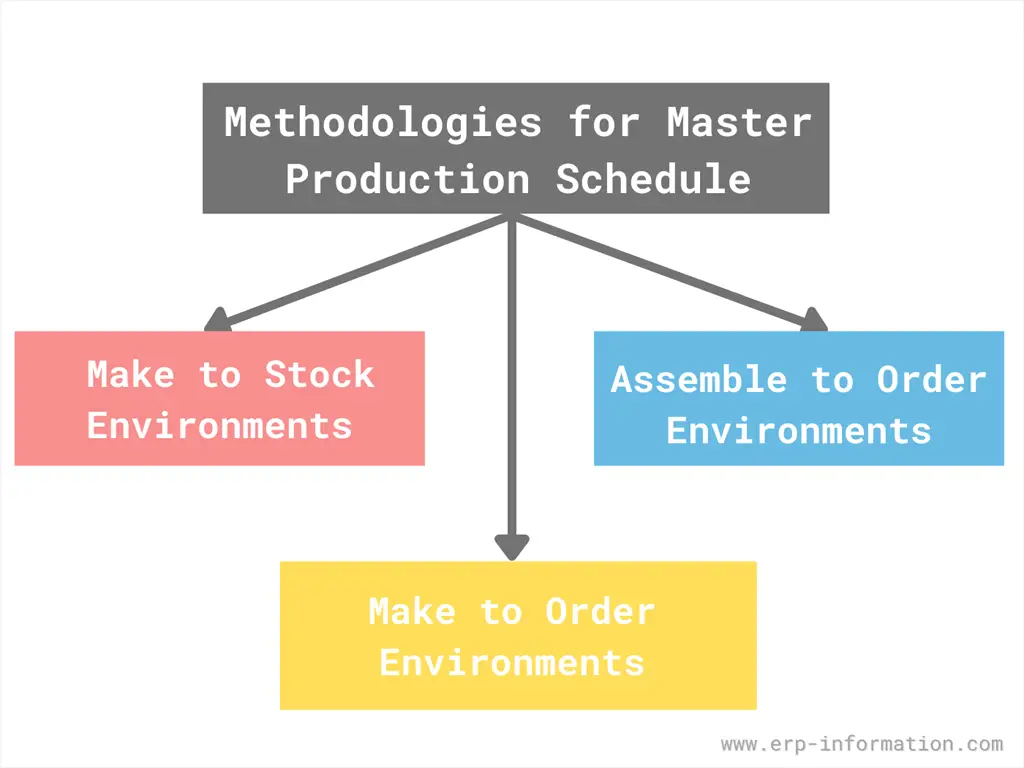

Different methodologies for Principal Production Scheduling

The Master Production Schedule needs to devise a final plan for manufacturing using all the currently available resources.

If the MPS emphasizes too many items, and then the plan proposed by the MPS does not apply to the manufacturers.

Autonomously from that, the production capacity suffers if the program proposed past MPS isn't detailed plenty.

As a general rule of thumb, master scheduling is only applicable in the particular instance where the smallest number of product alternatives are available.

Brand to Stock Environments

In this specialized scenario, a minimal quantity of items is assembled to grade a more significant number of components.

In this scenario, the Chief Product schedule would finish valuable items.

Make-to-Order or Build-to-Order Environments

In this case, various finishing goods are made from minimal raw materials. 1 of the great examples of this case is the manufacturing process of automobile vehicles.

The primary aim of the Master Product Schedule in the Make-to-Order environment would be the periodic arrangement of the bodily client orders.

Assemble-to-Order Environments

Gather-to-order environments utilize raw materials to produce subassemblies and the essential components effectively.

These components and sub-assemblies piece of work in harmony to grade various finishing goods.

In this technological surround, the Master Production schedule should emphasize the subassembly level.

MPS in each of these scenarios emphasize the specific surface area.

Benefits of Master Production Schedule

- It provides an effective and most reliable communication conduit with the sales team to facilitate the planning process.

- Effectively reduce the time incurred in the manufacturing process throughout the year.

- It acts as an effective barrier against the shortage of raw fabric and any unexpected mishap.

- Make necessary adjustments to address the fluctuation in demands while reducing the waste properly.

- It managed the cost incurred on manufacturing on behalf of the business organisation possessor and fabricated the most precise adding about the raw material requirements.

- It enhances the overall efficiency in the location of production resource.

- It acts as a foundation to construct, improve, and rail the sales forecast.

- It helps the organization's account department reach income and expenses by providing account statements like profit & loss statements and the balance sheets.

- It helps in the calculation of inventory levels.

Functions of Primary Product Scheduling (MPS)

The software system of Master Production Scheduling possesses too many attributes.

Before implementing the system of Master Production Scheduling, it is generally regarded as a good practice to analyze the critical aspects of this computerized system that facilitate product.

Here are the disquisitional functionalities of the Master Production Scheduling software arrangement.

Transforming Plans

This specific portion of the software speculates the corporeality of material, labor, and specialized equipment required to see the manufacturing goal.

Provide Alternative Production Routes

The Master Product Scheduling system produces a trial and error schedule that gives an culling route to achieve the production.

That would tackle any unexpected mishap that would ascend within the completion of production.

Utilization of Available Resources

Master Production Scheduling solution establishes the human relationship between the load and utilization of the mechanism and equipment deployed in the manufacturing process.

That allows for the best utilization of all the available resources and a more efficient product flow.

Establish Chapters Requirement

The Main Production Scheduling facilitates capacity planning by establishing formal capacity requirements.

Principal Product Scheduling facilitates the manufacturers to obtain the proper knowledge about the requirement of capacity.

Aid in Data Processing

MPS determines the best appropriate time for delivery. It consistently coordinates with the various direction information systems.

Principal Production Schedule Instance

Master Production Schedule (MPS) transforms the business organisation plans into the intelligent management of the impact of seasonality, promotion, and fluctuating demand.

Here is a typical existent-life instance,

A pump manufacturer sells ready-to-fabricated products. To successfully manage the sales, the pump manufacturer needs to get together these products earlier shipping them inside 48 hours after taking orders.

The time required for the completion of the product process is 1 twenty-four hour period. Although numerous components and subassemblies are still necessary for the successful manufacturing of the pump, these subassemblies and internal components enhance the production time from ii days to two months.

To successfully manufacture a pump inside 48 hours, the pump manufacturer must admission all the components required to manufacture finishing products.

FAQs

What is meant by chief scheduling?

Master scheduling is creating a master production schedule, which is a plan that outlines all of the organization'southward production tasks and their associated timeframes.

A master schedule is created in manufacturing and production to plan how much of each product will be produced. The programme considers time to come demand, the availability of resource, and the arrangement's production capacity.

Principal scheduling is also sometimes chosen aggregate planning or horizon planning. This is because it serves as a "framework" against which shorter-term plans (east.one thousand., daily, weekly, or monthly production plans) can be created and helps ensure that the organization produces simply what information technology can sell without making the excess inventory.

How is production planning unlike from the master product schedule?

Production planning is the phase that comes before the master product schedule. Production planning defines the higher production level and tiny details.

Product planning determines how many products should be produced. But MPS defines and decides the number of products made in a given time interval.

By following these 7 steps, you tin create a chief production schedule to help your business run more smoothly and efficiently.

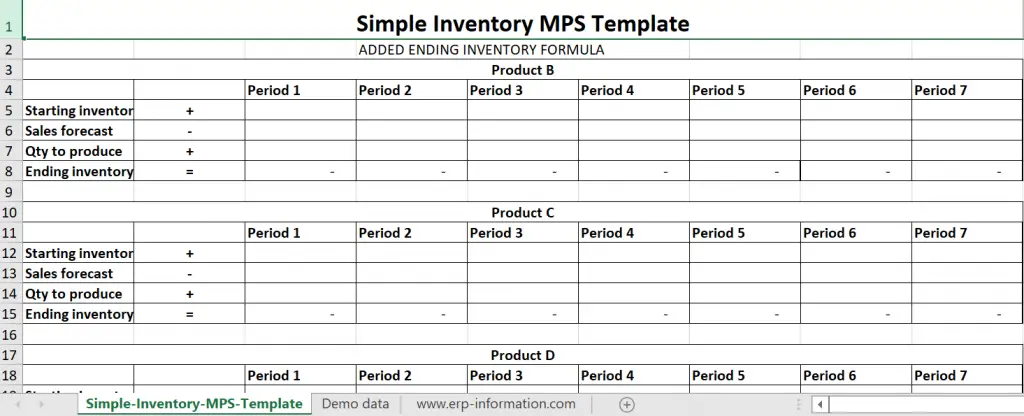

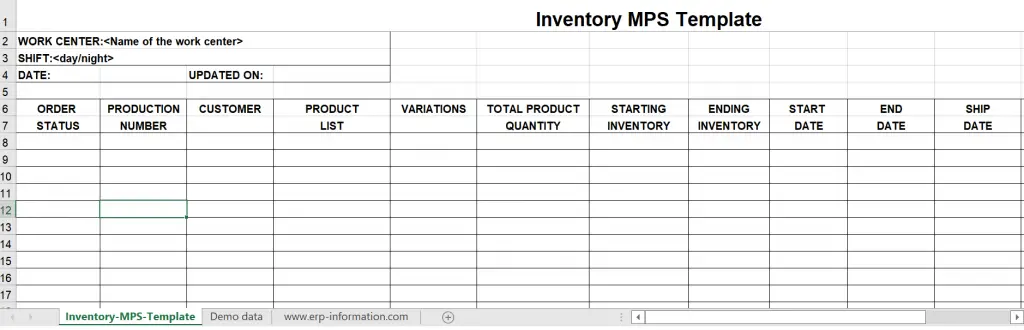

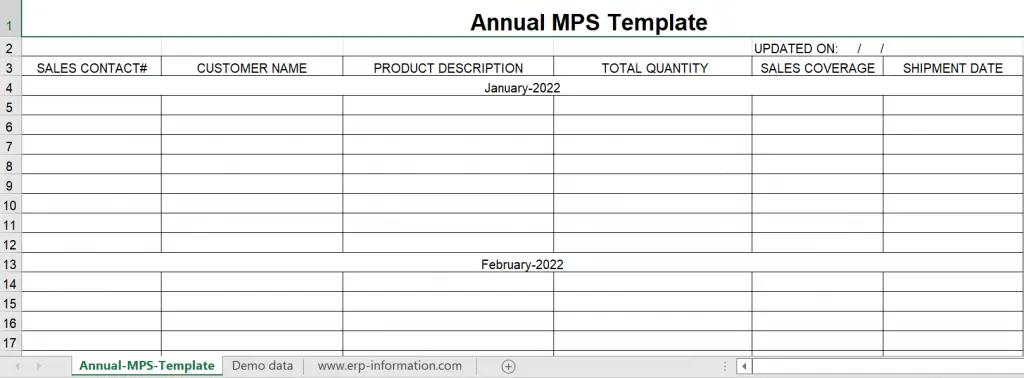

Download MPS Templates

Unproblematic Inventory Template

Full general Inventory Template

Annual Template

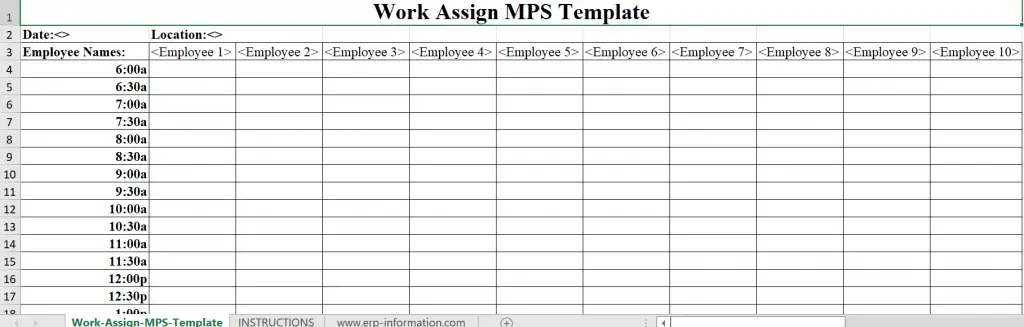

Work Consignment Template

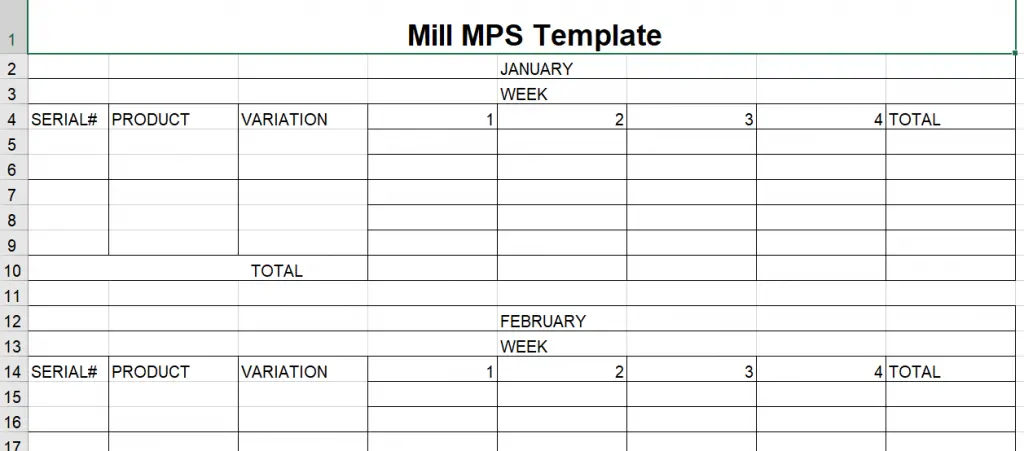

Mill Template

Determination

Master Product Schedule is more often than not regarded as the middle of manufacturing Enterprise Resource Planning because it correlates manufacturing and planning.

The MPS management system has been extensively used as a helpful tool for the nigh precise calculation of resources required to fulfill production plans.

It helps to identify production bottlenecks and potential bug. -MPS can help with forecasting, capacity planning, inventory management, and order fulfillment/production schedule.

With the MPS in identify, it is easier for a company to predict demand more accurately, which will reduce on-hand inventories. This also improves client service since customers are not waiting on products that may exist out of stock or unavailable at whatsoever given moment.

Source: https://www.erp-information.com/master-production-schedule.html

0 Response to "Why Draw a Master Production Plan"

Publicar un comentario